The circle of it: This company enables circular manufacturing by using robotics, design tools, and material tracking to disassemble electronics and keep their components and materials in continuous reuse

molg

Summary

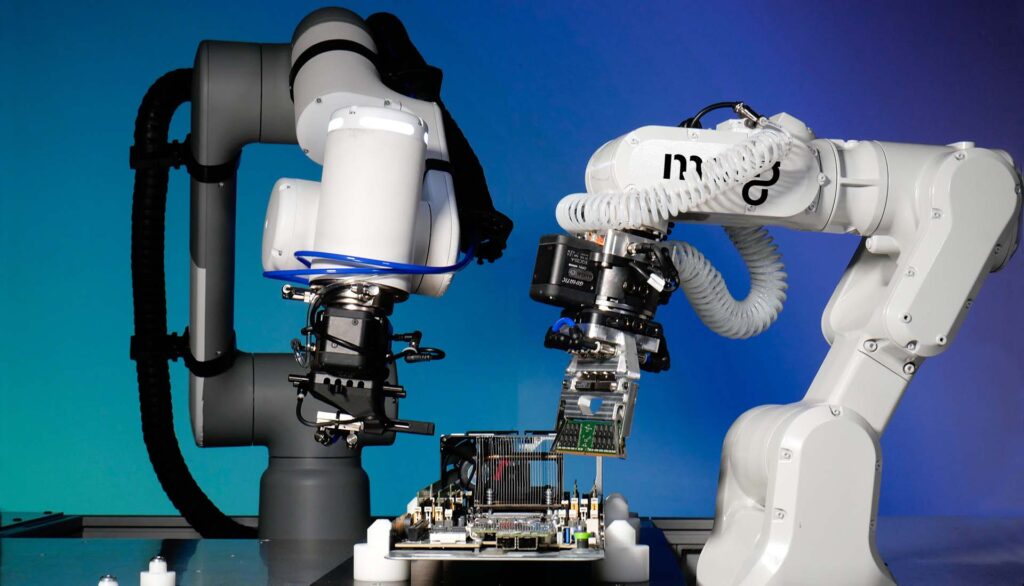

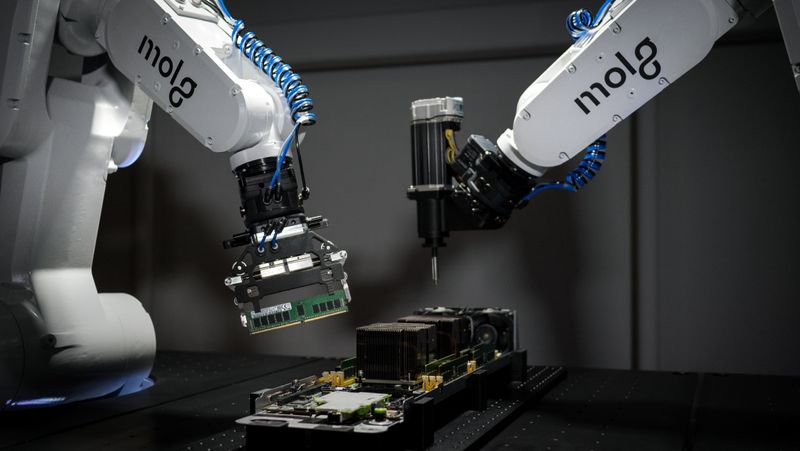

Molg is a circular manufacturing company that uses robotics, design tools, and material traceability to keep electronics and their components in continuous use rather than becoming waste. They build robotic microfactories that can precisely disassemble complex devices like laptops and servers to recover high-value parts for reuse, remanufacturing, or recycling, and they work with manufacturers to design products that are easier to take apart from the start. Through their open traceability standard, OriginMark™, Molg tracks materials and components across the product lifecycle to improve transparency and measure environmental impact, helping shift electronics from a linear “make-use-dispose” model to a circular one. (Source) In 2025, Molg is expanding through funding, government grants, and strategic industrial partnerships. Its collaborators include major technology and sustainability investors, global manufacturing leaders (like ABB, AWS and HP), electronics recyclers (like Sims Lifecycle Services), and academic partners — showing momentum in both technological development and ecosystem growth.

Story

Molg was founded in 2021 by Rob Lawson-Shanks and Mark Lyons with the mission to tackle the growing problem of electronic waste by rethinking how products are made and reused. After spending years in consumer electronics manufacturing, they saw firsthand how poor design and wasteful end-of-life processes caused valuable materials to be lost, so they set out to build robotic microfactories and design tools that enable circular manufacturing—where devices are designed for reuse and disassembled by robots to recover components rather than being discarded. (Source)

Pic credit: Molg (right and top)

“Well, first off, we could start by making things less sticky by not using glue and adhesives in electronic design! But on a more serious note, it’s really about forming strong partnerships across the entire ecosystem and pushing each other in our respective roles to make circularity the default way of doing things. We need manufacturers, users, recovery partners and second-life users all working together, challenging what’s possible, and continuously raising the bar on circularity until it’s just how we operate as an industry.”

Rob Lawson-Shanks in an interview

Founder(s)

Rob Lawson- Shanks and Mark Lyons

Headquarters

Chantily, Virginia

In business since

2021

Technology

Enabling circular manufacturing using robotic technology to disassemble electronics and make reuse feasible

Impact

Leave a comment