The circle of it: This company uses robots at waste management facility to increase efficiencies associated with recycling and recovering value from waste

amp robotics

Summary

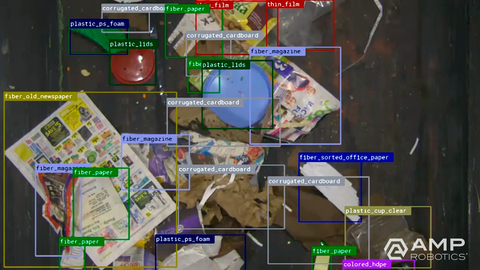

AMP Robotics uses artificial intelligence (AI) to scan through recyclables at waste management facilities to allow more recyclables to be captured from waste streams, producing a greater volume of high-purity secondary resources. This has the potential to significantly increase efficiency at recycling centers, where it is currently estimated that anywhere between 50-70% of recyclables are not actually recycled. Some of the reasons behind the low percentage of recycling have to do with difficulties associated with sorting out recyclables at the waste management facilities, a task that is currently done manually. The job of material sorting is physically demanding and is prone of human error. AMP Robotics uses cameras and AI to scan mixed waste streams and identify and sort different materials. It uses deep learning capabilities to allow for continuous improvement of the sorting and categorization of the recovered recyclable material. (Source) AMP’s AI also makes secondary sorting technically and economically feasible. Through its sorting model, AMP recovers mixed paper, metals, and a portfolio of #1-#7 plastics in a variety of form factors and attributes with high precision and purity, with a special focus on plastic blends uniquely enabled by AI. The company can then resell these commodities to end-market buyers and recover value from waste. (Source)

Story

Founder Matanya Horowitz has a Ph.D. in robotics from CalTech, where he had a chance to see what was working well in robotics and what remained a challenge. He saw that computer vision was becoming incredibly powerful, and started looking into areas where the applications of robotics and computer vision could be combined. This led him to recycling. Horowitz took about 2 years to develop the initial robot and then started talking to waste management facilities to implement the idea in various locations. Horowitz and his team also employ the robots at AMP’s own recycling facilities that buy waste that cannot be sorted from traditional waste management facilities and Material Recovery Facilities (MRFs).

Pic Credit: Business Wire (right) and The Robot Report (top)

“I believe the ability to recover recyclables from residual waste streams represents a major opportunity to increase national recycling rates. Today, the difficult-to-recycle material left over from MRFs is typically sent to landfill. This means that millions of tonnes of recyclables and material feedstock worth billions of dollars are lost to landfill despite the demand for recycled content from consumer packaged goods companies and manufacturers,”

Matanya Horowitz in an interview

Founder(s)

Matanya Horowitz and James Bailey

Headquarters

Boulder, CO

In business since

2015

Business type

for profit

Impact

Rate of material recovery at a waste management facility in Virginia increased by at least 10%

Technology

designing robots using AI and computer vision to robotically sort through materials, opening up market for secondary resources

Material

robots, AI, deep learning

Website

Leave a comment