The circle of it: This company has created technology to take textile waste and recycle them into new raw materials that can be used endlessly for new clothes instead of using virgin raw materials.

circ

Summary

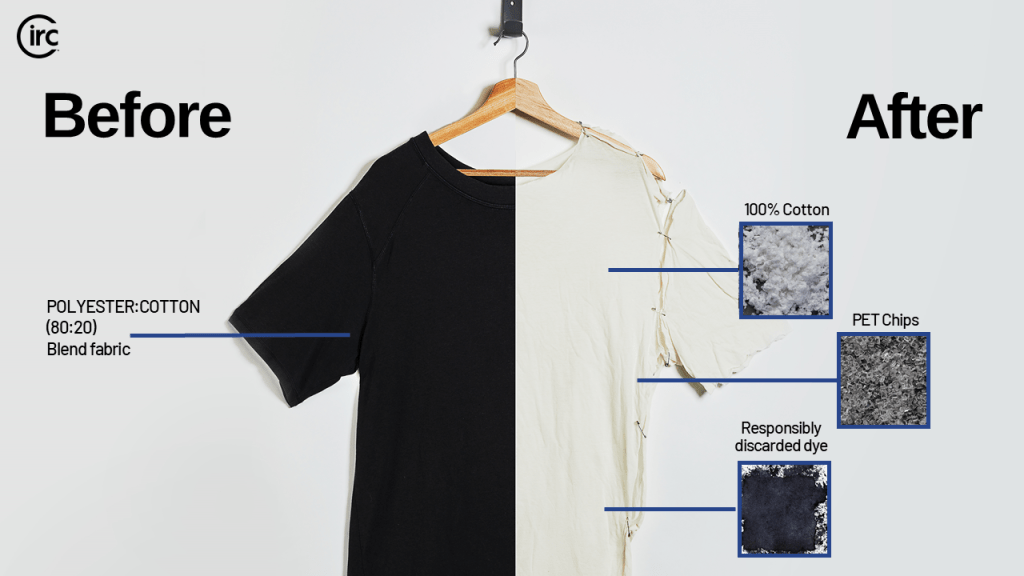

Circ is tackling the huge problem of waste in the fashion industry caused by using old clothes as the raw material to create new ones. Circ imagines a future where almost all clothes will be made entirely from recycled old clothes. By separating synthetic fibers (like polyester) from cellulosic content (like lyocell), the company recovers the majority of the raw materials in textile waste, so it can be remade into high quality fiber. The company’s process utilizes a mix of water, heat, pressure and chemicals to break down and cleanse textile fibers, allowing for the recovery of 90% of the original components. (Source) When polyester is broken down into it’s parts, high-quality cotton cellulose is produced, which can be used to create cellulosic fibers like lyocell, rayon, viscose and other such materials. Therefore, through this technology, the company is uniquely capable of separating and recovering mixed-textiles, specifically any blend of polyester and cotton, which accounts for most fabrics manufactured. (Source) The company collaborated with Zara to design a collection exclusively from the recycled fabric, which was released in April, 2023.

Story

Co-founder Peter Majeranowski had a business background working for companies in Easter Europe when got an idea from a famous immunologist, Hillary Kurowski, who was running a biotech company, to use an engineered non-smoking tobacco plant for biofuels. Majeranowski was interested in the idea because he was interested in democratizing energy rather than people being dependent on energy having to be transported from so far away, apart from the geo-political issues that come from traditional oil sources. Majeranowski started this company but didn’t find enough interest from venture capitalists. However, the company had developed technology to turn the tobacco pulp into paper. The company identified that one of the highest qualities of pulp or cellulose goes into clothing. And that’s when a Swedish trading company suggested running some old t-shirts through the company’s process to see if we could recover anything. Reiterating and pivoting on their intial technology, the company turned to the idea of using their technology to generate poly-cotton that is the raw material fro most clothing made today. (Source)

Pic Credit: Circ

“…the reality is most of the stuff and it sits in our closet unused. And so we like to talk about new models where you know clothing is is first of all designed for circularity is designed to be reused the the cradle to cradle philosophy is there that. The brands have a relationship with you but it’s not like you just sell. It’s almost like you’re leasing the molecules and we just keep recirculating them so you’re wearing the same molecules for life and the way to do that in a very practical way is is to have recycling hubs all over the place using technology like search. Having a robust collection system linking this all together and I think digital has a huge place to play here in tracking this stuff connecting consumers with all these ah these collection points digitally. And then getting into facilities like r so can be recycled over and over again.”

Peter Majeranowski in an interview

Founder(s)

Peter Majeranowski and Iulian Bobe

Headquarters

Danville, VA

In business since

2011

Business type

for profit, B corp

Impact

Technology

recovering and separating fibers from old clothes, creating newyarns to be used in new clothing

Material

used clothes

Website

Leave a comment